Key takeaways:

- Autodesk and its customers demonstrated the maturity of its manufacturing solutions, including PLM/CADCAM/CAE capabilities provided through Fusion 360

- It showed that its products are ‘industrial strength’ and provide innovative capabilities such as additive/subtractive technology

- Smaller, hi-tech companies are attracted to these products as they can start small and then scale taking advantage of its cloud capability and subscription model.

The Accelerate conference focuses on manufacturing and Autodesk’s PLM/CADCAM software. Although Autodesk is better-known globally and with some investors for its BIM/AEC capabilities, manufacturing has always been a core area. Autodesk targets, and is very successful with, up-and-coming innovative companies either in or moving towards the high-tech area and using new technologies such as generative design, Additive Manufacturing (combined with subtractive), and simulation.

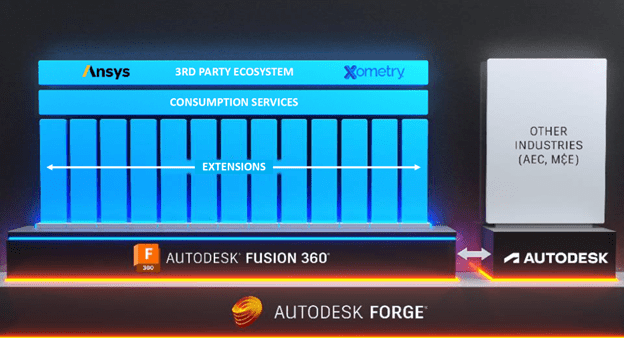

It was interesting to see the maturity of Autodesk’s manufacturing solution (concisely presented by Stephen Hooper – pictured above) which includes a suite of PLM/CADCAM capabilities with Fusion 360 on top of its core Forge platform – see picture below. Hooper explained how recently-acquired Upchain provides multi-tenanted cloud presence for PLM and PDM, while Prodsmart (another recent acquisition) enables manufacturers to automate and connect processes and provide production insights from ordering through to shipping. Autodesk also acquired Delcam several years ago, bringing with it serious CAM capabilities such as PowerMILL and PowerINSPECT, along with its 5-axis subtractive machining and various additive manufacturing technologies. For CAE and simulation, it has a partnership with ANSYS.

Hooper stressed how the rising cost of goods, problems in the global supply chain, and shortage of skills are reinforcing the need for CAD/CAM/CAE tools that improve productivity. This technology also reduces cost – making it possible to onshore production, become more flexible to market conditions, and facilitate digital collaboration (see diagram below).

Accelerate showcased companies such as Final Aim, Seymour Powell, Sandvik Coromant, and EDAG, that are using Autodesk products.

Final Aim

Final Aim is a Japanese company specializing in new product design in the high-tech sector. @Yasuhide (Yasu) Yokoi, Co-Founder & Chief Design Officer, showed some innovative case studies based on its Web3 platform, including:

- ‘Camello’, an autonomous delivery robot now in use in Singapore, developed with OTSAW (see image below)

- a small mobility vehicle for Honda (see image below)

- a modern take on the Samurai sword designed with generative design techniques

All of the above used Fusion 360 and some used generative design, 3D printing, and blockchain.

It was also interesting to note that from 2007-2014, Yasu was truly involved in digital transformation as he designed the D4 Flagship DSLR and other digital cameras that replaced film.

Seymour Powell

Seymour Powell is a UK company that provides product design solutions using game engine technology.

@Craig Bunyan presented case studies on cabin interior designs for Virgin Galactic and other innovative companies, using ‘extended reality’ for collaboration – enforced due to the COVID-19 pandemic when the collaborators couldn’t meet in person and yet key design decisions had to be made.

Sandvik Coromant

Although not exactly ‘up-and-coming’ (established in Sweden in 1862) and known as a supplier of cutting tools rather than a ‘high-tech’ product company, Sandvik Coromant is moving into manufacturing software with the recent acquisitions of Dimensional Control Systems, ICAM Technologies Corp., Fanar, Cambrio, DWFritz Automation, CNC Software Inc., and CGTech.

Jonas Strom (Software Product Manager) and Andreas Hansson (Digital Offer Manager), explained how Sandvik is helping to ‘automate the manufacturing value chain to support efficiency and reduction of waste’.

Sandvik stressed the importance of tool selection and material to the final product and is working with Autodesk and other PLM/CADCAM companies to bring the decision-making closer to the designer. They also highlighted issues in hiring and training younger and more diverse staff into manufacturing.

EDAG

As a well-established company, with 50 years’ experience supplying engineering design and development services to automotive OEMs and T1 suppliers, EDAG is quietly disrupting the automotive ‘OEM/Tier’ model by developing a new vehicle that not only sits at the top of the ‘OEM’ pyramid, but also disrupts the traditional vehicle design and release process.

The ‘CityBot’ is a modular, autonomous, electric vehicle with a power unit that can attach to a variety of trailers or cabins providing various functions from people-carrying to goods-delivery, and even trash-collection. See images below and https://www.edag-citybot.de/en/ for more information.

[from https://www.edag-citybot.de/en/vision/ ]

In the same way that ARM provides chip designs for mobile phones, EDAG provides the design and manufacturing experience instead of building the vehicle (other than the prototypes). The production vehicles will be made by experienced automotive manufacturers so that EDAG will be not held back by designing and building production facilities, supply chains etc.

Sebastian Flügel presented their ‘Closed Loop Engineering process’ used to design the EDAG #CityBots using live data as input to #generativedesign to continuously improve the product. He described this type of development as ‘VUCA’ (Volatile, Uncertain, Complex, Ambiguous).

EDAG is also disrupting the conventional automotive industry model in other ways: instead of ‘releasing new models’ every few years – encouraging the replacement of the previous model – the CITYBOT is continually being refined using feedback from the sensors that monitor all aspects of its performance.

Software technology is key to the project in several ways:

- Autodesk Fusion is used to design the vehicles and components, and to collect the feedback from sensors.

- Fusion also supports generative design and digital twin concepts that are used in the development.

- Other software is used to control all the sensors (camera, LIDARs etc.), collect their feedback, analyse the data, autonomously drive the vehicles, and manage the traffic network

The biggest problem now with exploiting autonomous vehicles is when they have to coexist with human-driven ones, so the first targets are areas where humans can be excluded. The first production trial will be in Frankfurt airport – on the air-side apron where movements are tightly controlled and can be limited to autonomous vehicles. Other smaller implementations have been in warehouses, and city trials (in controlled areas) are being planned.

These examples demonstrate the maturity of Autodesk’s manufacturing solution with its suite of PLM/CADCAM/CAE capabilities provided through Fusion 360 on top of its core Forge platform.

Supporting information

https://www.home.sandvik/en/investors/acquisitions/

SANDVIK ACQUISITIONS

The table shows completed acquisitions. For presentations related to acquisitions, go to the page for presentations.

| Year | Company (link to press release) | Business area1) | Share,% | Revenues MSEK |

| 2021 | Dimensional Control Systems | SMM | 100 | 92 |

| 2021 | GWS Tool Group | SMM | 100 | 41 MUSD |

| 2021 | ICAM Technologies Corp. | SMM | 100 | 30 |

| 2021 | Fanar | SMM | 100 | 175 |

| 2021 | Cambrio | SMM | 100 | 628 |

| 2021 | DWFritz Automation | SMM | 100 | 720 |

| 2021 | CNC Software Inc. | SMM | 100 | 60 MUSD |

| 2021 | Chuzhou Yongpu | SMM | 67 | 400 |

| 2020 | CGTech | SMM | 100 | 470 |

| 2020 | Miranda Tools | SMM | 100 | 200 |

| 10 acquisitions for SMM in 2020/21 | ||||

| 2020 | Allied Construction Products LLC | SMRT | 100 | 275 |

| 2020 | Quimmico Centro Technológico (QCT) | SMS | 100 | 90 |

| 2020 | Summerill Tube Corporation | SMT | 100 | 100 |

| 2021 | Kwatani | SRP | 100 | 175 |

| 2021 | Accuratech Group | SMT | 100 | 75 |

Business areas:

SMM=Sandvik Manufacturing and Machining Solutions

SMR=Sandvik Mining and Rock Solutions

SRP=Sandvik Rock Processing Solutions

SMT=Sandvik Materials Technology

SMS=Sandvik Machining Solutions

SMRT=Sandvik Mining and Rock Technology

Yasuhide Yokoi – “Yasu” – FINAL AIM

Designed products include digital SLR cameras

・ D810 – Ultra high-resolution DSLR camera for studio photographers.

・ PROSTAFF 5 – Re-branding and designing laser range finder for golfers and hunters.

・ D5300 – Consumer DSLR camera with challenging colors variations.

・ D7000 – Launch of a new DSLR camera line for emerging high-amateur

・ D4 – Flagship DSLR camera for top professionals.